Some of our riders will be testing models in Whistler this week. (Skier: Mike McCabe)

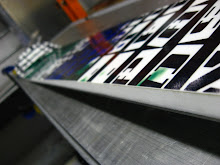

Folsom Customs was born from the idea of a small freeski company that was not concerned with volume, but a custom-made product. We wanted to be based right here in the

It has taken us three years, but each ski we offer has been thoroughly field-tested with multiple flex patterns. So when we build a ski for you, we not only fit you to a shape but also to a tested flex pattern. This flex pattern will then be tailored to your personal goals as a skier and based off your personal input. We don’t start building your ski until we take your order- they really are one of a kind. It may take a little longer to get a pair, but it will be worth it.

The benefit of ordering from Folsom Customs is that you not only get a custom-made ski, but you get a partner for the future. We are all evolving as skiers and our requirements for a ski often change as we evolve. What is unique about Folsom Customs is that your next pair can be built off of your personal notes from your current ski. Your ski can evolve as you evolve as a skier. It is an ongoing process.

Folsom is also committed to environmental sustainability. As a small custom shop, we are able to make the right choices when it comes to our waste and energy use. By selling local, using sustainably harvested core materials, recycling and working on ways to keep old skis out of landfills (ski picnic table anyone?), we strive to leave a small footprint. We want the next generation to enjoy skiing as much as we do.

Thank you for stopping by. We look forward to working with you soon.

Folsom Customs- Handcrafted. Durable. Sustainable.-